Article Contents

Introduction

The polymer industry is moving full steam ahead in 2023.

ABS plastic is one of the most versatile thermoplastic materials available and continues to push the polymer industry forward, even now, 70 years after being introduced into the market.

In this ABS polymer growth statistic roundup, you’ll learn:

- >ABS Polymer Growth Statistics 2023

- >Injection moulded plastics market projections

- >What is ABS in polymer?

- >Why is ABS a good plastic?

- >Is ABS plastic good quality?

- >Is ABS better than plastic?

ABS Polymer Growth Statistics 2023

Acrylonitrile Butadiene Styrene (ABS) Market Size is projected to reach US$ 57.24 Billion by 2030, growing at a compound annual growth rate of 6.7%.

- >Global ABS demand is expected to reach 20.6 million tons by 2023, growing at a CAGR (Compound annual growth rate) of 4.5% from 2018 to 2023.

- >Asia Pacific is the largest market for ABS, accounting for over 50% of the global demand in 2018.

- >The automotive industry is one of the largest end-use industries for ABS, driven by the increasing demand for lightweight and fuel-efficient vehicles.

- >The electrical and electronics industry is also a significant end-user of ABS, driven by consumer electronics and appliance demand.

- >The construction industry will see increased demand for ABS for various applications, including pipes, siding, and roofing.

- >The global ABS market was valued at USD 16.2 billion in 2019 and is expected to reach USD 22.4 billion by 2025, growing at a CAGR of 5.3% from 2020 to 2025.

- >The ABS market is highly consolidated, with a few key players accounting for a significant market share. The top five players in the ABS market are LyondellBasell Industries, SABIC, BASF SE, The Dow Chemical Company, and Formosa Plastics Corporation.

- >The medical industry will experience a rise in demand for Acrylonitrile Butadiene Styrene (ABS) due to its use in various medical devices and equipment, including prosthetics, hearing aids, and orthopaedic implants.

- >ABS plastic demand is rising in the packaging industry due to its versatility in food, cosmetics, and pharmaceutical packaging.

ABS polymer growth statistics show steady growth for the market, reflecting a positive sentiment for the year 2023.

Injection moulded plastics market projections

The global injection moulded plastics market size reached US$ 278.57 Billion in 2021. Moving forward, the market is expected to reach US$ 363.61 Billion by 2027, demonstrating a compound annual growth rate of 4.54% during 2021-2027.

Injection moulded plastics are manufactured using thermoplastics, such as:

- >Acrylonitrile butadiene styrene (ABS).

- >Acrylonitrile styrene acrylate (ASA).

- >High-density polyethene (HDPE).

- >Low-density polyethene (LDPE).

- >Polycarbonate (PC).

- >Polyamide (Nylon).

- >High-impact polystyrene (HIPS).

- >Polypropylene (PP).

What is ABS in polymer?

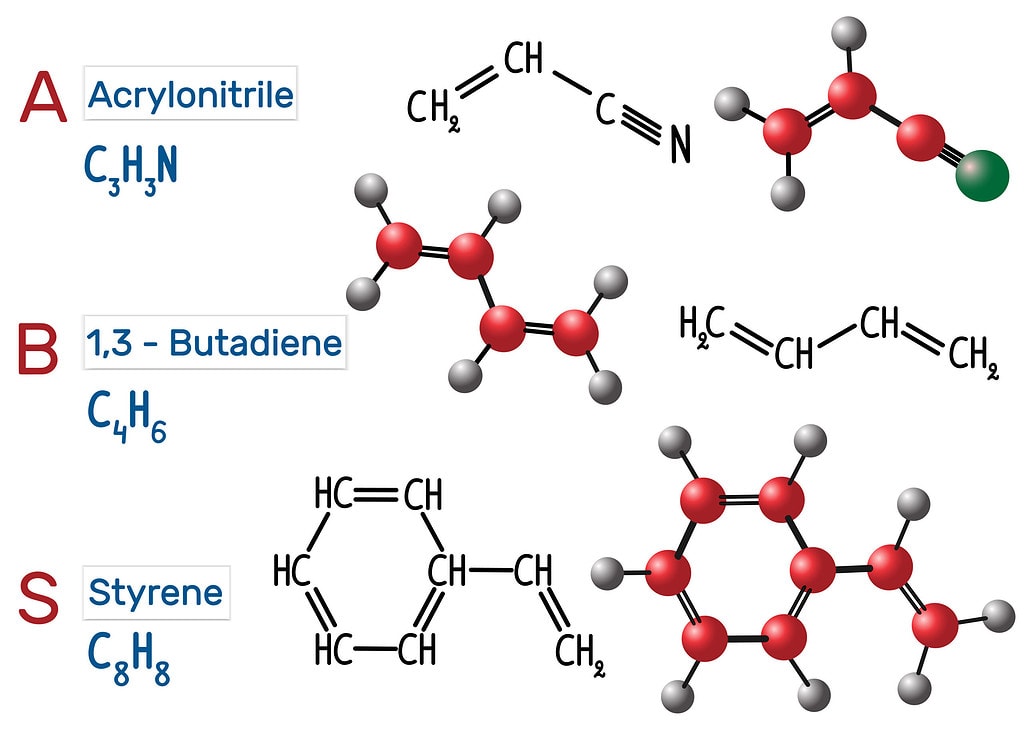

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic polymer that is a copolymer made up of three different monomers: acrylonitrile, butadiene, and styrene. These monomers are combined in different ratios to produce ABS with varying properties.

Acrylonitrile imparts high strength and heat resistance to ABS, butadiene contributes flexibility, and styrene adds a glossy finish. This blend of properties makes ABS versatile for a wide array of applications.

Manufacturers commonly use ABS in toys, automotive parts, household appliances, electronic housings, musical instruments, and other consumer goods. It’s also a favoured choice for 3D printing filaments.

Processing ABS is relatively easy due to its good electrical insulation properties. It can undergo injection moulding, extrusion, or thermoforming. Additionally, ABS polymer can be machined, sanded, or painted. Its lightweight nature makes it ideal for weight-sensitive applications.

ABS can be reheated and reshaped multiple times as a thermoplastic polymer without losing its mechanical properties. However, it is sensitive to UV light, which can cause brittleness over time.

One of the critical advantages of ABS is its recyclability. This feature allows for producing new products from recycled material, contributing to a more sustainable manufacturing process.

Despite these advantages, ABS polymer has some limitations. It exhibits low chemical and flame resistance, restricting its use in some applications.

Why is ABS a good plastic?

Overall, ABS is considered a good plastic due to its combination of properties, durability, ease of processing, good electrical insulation properties, lightweight and recyclability which makes it suitable for a wide range of applications.

Several reasons make ABS (Acrylonitrile Butadiene Styrene) a good plastic:

- >Versatility: ABS’s combination of properties, including strength, toughness, and heat resistance, makes it a versatile material suitable for various products across various applications.

- >Durability: As a thermoplastic polymer, ABS can be reheated and reshaped multiple times without losing its mechanical properties, ensuring durability for products that require repeated use.

- >Ease of processing: One of the critical advantages of ABS is its ease of processing. Manufacturers often prefer ABS, as everyone can efficiently handle the material. Various methods, such as injection moulding, extrusion, and thermoforming, can also be machined, sanded, or painted.

- >Electrical insulation: ABS is famous for electronic housings and other applications requiring good electrical insulation properties.

- >Lightweight: ABS’s lightweight nature makes it ideal for applications where weight is a concern.

- >Recyclable: Another significant benefit of ABS is its recyclability. This feature allows it to be repurposed for producing new products, making it an environmentally friendly option for manufacturers and designers. It is, therefore, increasing its overall sustainable credentials.

Is ABS plastic good quality?

ABS (Acrylonitrile Butadiene Styrene) is generally considered a good quality plastic due to its combination of properties and versatility. However, like all materials, ABS has its own set of advantages and limitations.

One should consider its limitations when choosing ABS plastic for a particular application.

- >Low resistance to chemicals: ABS has a low resistance to chemicals, which limits its use in certain applications.

- >Low flame resistance: ABS has a low flame resistance, which limits its use in certain applications.

- >UV sensitivity: ABS is sensitive to UV light and can become brittle over time when exposed to it.

Overall, the properties, versatility, and durability make ABS a good quality plastic.

Is ABS better than plastic?

ABS is a thermoplastic polymer that is known for its toughness, strength, and resistance to impact and chemicals. It is often used in automotive parts, toys, and household appliances. Plastic, on the other hand, is a general term that refers to a wide range of synthetic or semi-synthetic materials that can be moulded into different shapes.

Manufacturers commonly use both ABS (Acrylonitrile Butadiene Styrene) and plastic, but they differ in properties and uses.

Different types of plastic have different properties, but many are lightweight and durable. Whether ABS is better than plastic depends on the specific application and properties required.